The production of a Jew's harp is much more

complicated than it looks at first glance.

The most

important part is the swinging spring.

There are at least

3 different vibrations that influence each other.

1.)

Deflection vibration of the spring

2.) torsional vibration of the spring

3.) Natural vibration of the angled part at the stop

This mixture of different vibrations gives the

sound of a Jew's harp.

All of these vibrations are dependent

on:

- the length of the spring

- the width of the feather

- the thickness of the spring

- the material of the spring

- Tapering and thickening at various points on the spring

- the height of the angled part

- the shape of the upper end

Theoretically, it is possible to produce the

same tone by making the spring shorter and wider.

Unfortunately, the other vibrations involved are changed so that in the worst case it can lead to mutual extinction.

You can only build a good jaw harp if all the vibrations are right. This is what makes the manufacture of good jaw harps so difficult.

Another challenge is high precision in production, so that the vibrations generated are loud and clearly audible.

Are

important:

- The distance between the bracket and spring

- horizontal and vertical parallelism between bracket and spring

- The cross-section at the edge of the temple

- the angle on the spring

- the type of spring attachment

By varying all

of these things you can make a Jew's harp into a high quality

instrument.

Calculations of these things are only possible to a limited extent and are highly complex.

I myself have built a lot of jaw harps with the same basic tone, but the sound is never exactly the same.

Here is an

overview:

modification | Result |

|

|

Spring longer | Low tone / vibrates for a long time / strikes the temple lightly |

Spring shorter | High tone / vibrates shorter / too hard stop |

Spring wider, | Low tone / vibrates shorter / different torsional vibration |

Spring narrower | High tone / vibrates longer / different torsional vibration |

Spring thicker | High tone / vibrates shorter / hard stroke |

Spring thinner | Low tone / vibrates longer / hits the temple lightly |

Spring harder | High tone / breaks light / hard stroke |

Spring softer | Doesn't swing / bends easily / does not keep the mood |

large distance between frame and spring | Less overtones |

small distance between frame and spring | Strikes the frame |

Parallelism frame-spring | Many overtones / different overtones |

Ironing cross section | Different overtones in connection with the spring cross section |

Spring section | Different overtones in connection with temple cross-section |

Spring attachment too loose | Spring strikes the bracket / loosens |

Spring attachment too tight | Little overtones / vibrates poorly /How slowed down / breaks more easily, |

Height of the stop part | Affects volume / duration of oscillation / natural vibration / pitch / torsional vibration |

The second important part of the instrument is the player's mouth, throat and lungs. In this way, the tones generated by a Jew's harp are filtered, amplified

or extinguished. The same Jew's harp sounds different with different players.

To

put it simply: a small resonance room amplifies the high notes. A

large resonance room, in which the lung volume is used, reinforces

the low notes.

The material used is just as relevant for the manufacture of a Jew's harp as the type. Coatings of the spring usually change the sound very drastically.

Chromium, zinc and tin should generally be rejected.

For example, food-safe colors, gold, silver, polished steel, stainless steel, bronze or untreated wood are harmless to health.

Nickel, aluminum and corroded brass, various types of blackening (mostly black jaws), treated wood and solvent-based paints can be of concern.

If in doubt, you should ask the manufacturer.

I use nickel silver to make my Jew's harp. This is rustproof. In the past, cutlery was made from it.

AIt

all starts with cutting round material to the right length. I use an

old hand lever eccentric press from my grandfather, who used to make

handguns with it.

With this, the basic tone of the Jew's harp is

determined

The basic shape of the jaw harp is then determined in two steps.

These devices are my father's own developments.

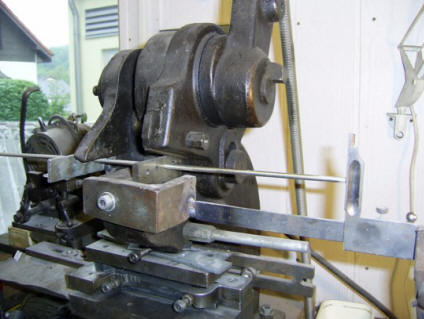

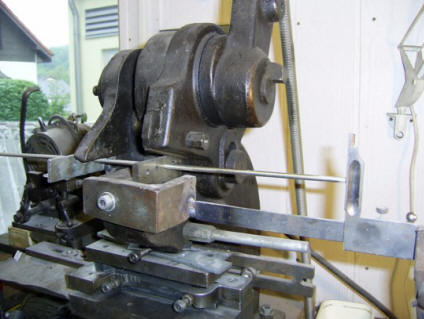

The shape of the

frame is now milled on a

very old milling machine, which also comes from my grandfather's

inventory.

Then the holder for the spring is milled, if possible in the middle, so that the spring fits in well and without tension.

The Jew's Harp is now processed with various files until I am satisfied with all angles and edges.

Whether

the jaw harp sounds good can only be seen at the wedding when the bow

and feather are combined.

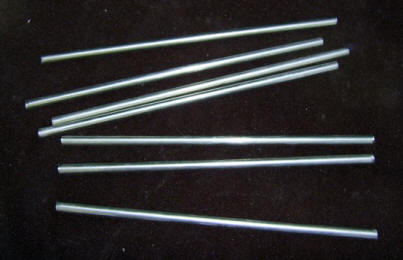

The material of my feathers is

high quality spring steel in different thicknesses.

A piece adapted to the jaw harp is cut out of it.

This must

be straightened until it is absolutely straight.

A crooked

spring doesn't swing properly.

The spring is now ground from all sides. It is still too hard to file.

Now the spring is 'started', a process for the targeted hardening or softening of steel

Now the spring is inserted carefully and tension-free into the jaw harp.

After the spring is inserted straight and parallel to the legs, it is carefully riveted.

I use an old spindle press for this.

A magnifying glass is used to check whether the spring is straight.

Next, the spring is bent at right angles and rolled up at the front.

Finally, I polish the Jew's Harp to a high gloss.

If everything worked out, the Jew's harp sounds good and the tone is right, the Jew's harp gets the stamp "Zella-Mehlis", "Schlütter" and the key.

Now it is tied to a wooden block and is ready for dispatch.

Have fun playing.